Description

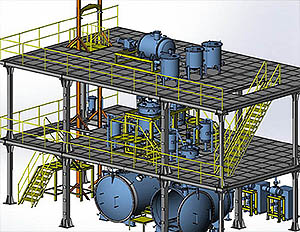

This equipment is special for epoxy resin casting dry type transformers, bushings, current transformers, potential transformers, HV switch insulators, arc-distinguish coils and other electric apparatus.

It is applicable for with-stuffing casting and without-stuffing casting.

It is suitable for degassing, mixing and casting high polymer materials under vacuum condition, such as bisphenol-A, outdoor-type epoxy resin, polyurethane, etc.

It is applicable for processing both mixed material with stuffing added by user and double-component pre-mixed stuffing, very flexible.

The equipment system can be added or reduced according to user’s requirements. It can be modularly rigged. It is characterized by convenient installation, easy operation, and high automation.

Main features

-Perfect vacuum system: the whole process is carried out under vacuum condition.

-Reliable metering system: there are two kind of metering methods based on different process requirement:

Feeding pump + electronic scale (for casting with stuffing)

Metering pump + static mixer (for casting various kind products)

-Advanced and safe heating technology:

Mixing tank is heated by , good temperature uniformity, high precision temperature control

Casting tank is heated directly by electric heating plate

-Advanced & reliable metering and control system: controlled by computer, key process and those easy to be mis-operated are controlled interlocked; Process revising, process curve recording, process parameter adjusting, can be achieved by computer very conveniently. The whole metering control and vacuum control are all full pre-set automatic.

Equipment Classification

Basic type vacuum (pressure) casting equipment

Dynamic mixing type vacuum (pressure) casting equipment

Static mixing type vacuum (pressure) casting equipment

◇ Basic type vacuum (pressure) casting equipment

Comprised of one set of vacuum mixing tank and one set of casting tank. It is of simple structure, convenient maintenance, low investment.

However, because there is only one set of mixing tank, mixture should be metered and controlled manually. And so productivity is normal.

◇ Dynamic mixing type vacuum (pressure) casting equipment

|

|

|

(full automatic dynamic mixing with stuffing) |

(full automatic dynamic mixing without stuffing) |

This kind is developed based on the basic type by adding some auxiliary equipment, such as pre-mixing system, metering & transmitting system (or stuffing bag discharging device).

Advantages: high automation; record process curve and every kind data; equipped with complete interlock protection measures; Productivity is several times than that of basic type.

Disadvantages: technology is worse than static mixing type; residual quantity of final mixture can’t be controlled easily; mixture waste is big (comparing to static mixing technology)

◇ Static mixing vacuum (pressure) casting equipment

|

|

Advantages:

-Mixing progress can be controlled accurately, short mixing duration, fresh mixture, perfect flow property; Thus raise wetting properties to windings, ensure activity of mixture. It solves the gelatin aging problem which is caused by long-term stirring of dynamic mixing.

-Material can be mixed whenever needed, shortens production cycle, raises productivity; No need to worry about insufficient material caused by mould leakage and thus there will be no residual material every time, saving materials.

-Metering pump is piston pump, carborundum pump body; servo motor drive, transmitted by precision screw rod; metering progress is controlled by program, can be metered simultaneously.

-Because metering pump can resist high pressure, mixture can be casted in high speed and thus arises scouring effect, reducing stuffing deposition inside pipelines. So this method is more suitable for casting dry-type transformer with stuffing.

-Manual casting valve is replaced by automatic rotating casting distributor. Casting progress can be pre-set by computer, full automatic casting progress.